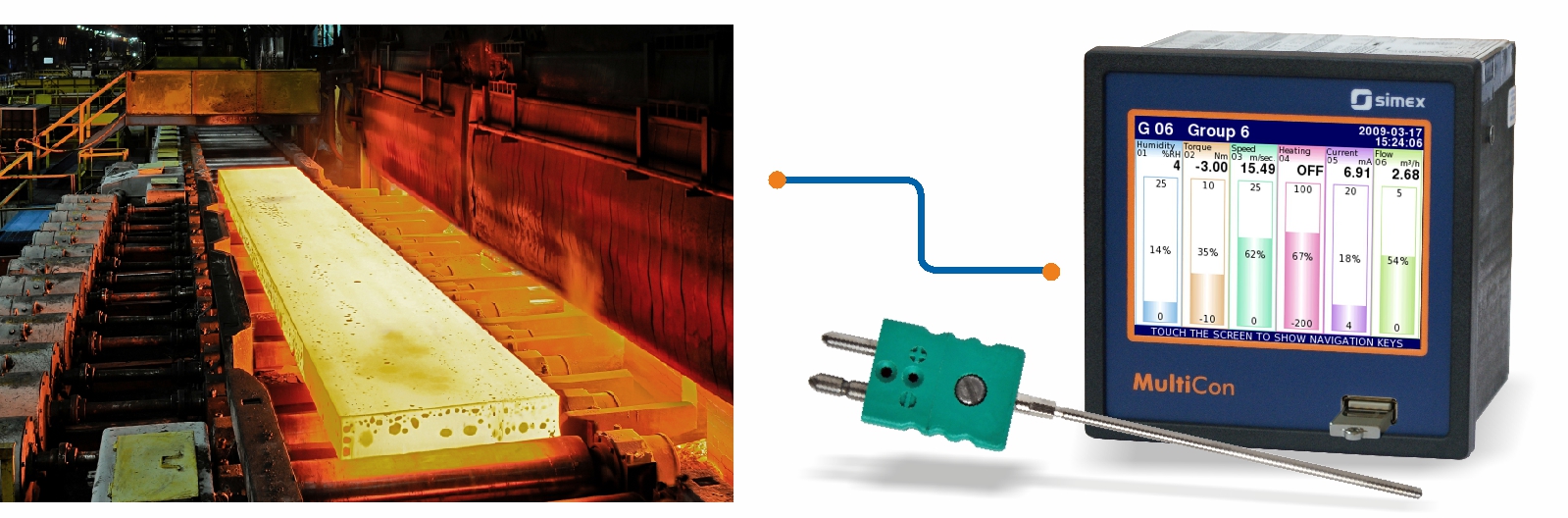

MultiCon and SCT300 in the steel hardening process

In the following newsletter we would like to present an example of an interesting application combining a series of our Temperature Sensors with the flagship CMC-99 recorders. In the steel hardening process, the MultiCon CMC-99 controller with the SCT300 sensor ensures precise temperature measurement, which is crucial for the processing quality.

The application uses the CMC-99-PS42/ETU/IO4/TC8/E-101 model in cooperation with the Simex SCT300 sheathed temperature sensor.

Signal inputs

The TC8 module consists of 8 thermocouple inputs used to measure temperature at various stages of the hardening process.

The IO4 module has 4 4-20 mA outputs, allowing you to control appropriate devices that adjust the temperature in the process

Communication

The ETU module has an Ethernet port, thanks to which the user can remotely monitor the temperature and be informed about any deviations.

SCT300

Measurement range: -40°C to +1200°C (for type K)

Measuring element: K-type thermocouple

Cover: Inconel 600 alloy, diameter selectable in the range of 1.5...8 mm

Accuracy: compatible with class 1 or 2

Usage:

- Electric Hardening Furnace Control: monitoring and precisely maintaining the temperature in the hardening furnace.

- Cooling Monitoring: tracks the steel temperature during cooling, ensuring that mechanical properties are achieved.

- Tempering Control: monitoring the temperature during the tempering process, which is crucial to the properties of steel.

- Data Logging: the CMC-99 records data from the SCT300, enabling analysis and optimization of the hardening process.